7.2 A Practical Guide to Troubleshooting

There are many reasons why an adhesive might fail for a particular joint; therefore, while the list below is not necessarily comprehensive, at least one of the items listed is likely to be evident in any given failure.

Failures can be categorised into four main areas:

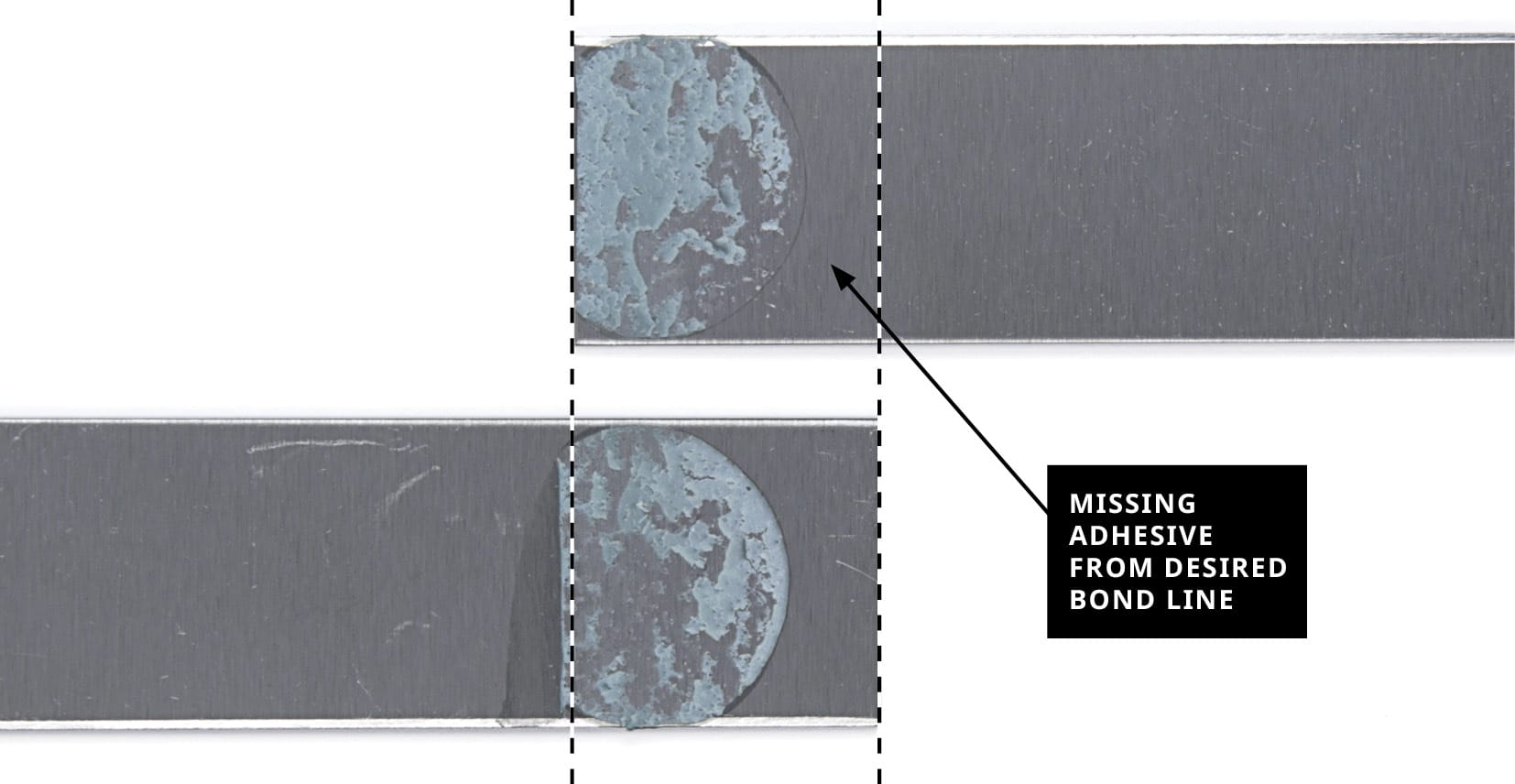

7.2.1 ’No ADHESIVE’

Though this might seem obvious, it is critical that there is sufficient adhesive volume to fill the joint. Joint starvation (lack of adhesive) can often be the reason for poor joint strength (see Section 5 for gap requirements). In some applications, air voids and cavities can mean the difference between a ‘good’ or ‘bad’ joint, especially if the adhesive is required to act as a sealant as well as an adhesive.

The first step of visual inspection of a failed component is to determine the quantity of adhesive in the joint; this may be the total surface area of the bond line, which shows evidence of adhesive coverage, or the total gap fill. Visual inspection is relatively straightforward with clear components, but with opaque substrates, it can be difficult to ascertain whether the adhesive has fully filled the joint.

As some adhesives will fluoresce under UV light, this is another method that may be employed during the inspection process. UV light becomes most useful when the adhesive is a similar colour or texture to the substrate, as the UV fluorescence will highlight the presence of the adhesive.