5.4.3 Fluid Characteristics of Adhesives

Several additional characteristics should be considered when specifying an adhesive for an application. As with any unique fluid or paste, there will be several properties unique to the particular chemistry that will affect how and where it can be used.

Regardless of the chemistry, all adhesives exhibit one or more of these properties:

- Thixotropy

- Viscosity ranging from ‘water thin’ to paste (i.e. 1 mPa.s to greater than 200,000 mPa.s)

- Adhesive texture, i.e. ‘stringy’

- Viscosity/temperature relationship sensitivity

- For 2C adhesives: Viscosity changes over time after mixing

5.4.4 Technology-Specific Characteristics

Each technology, chemistry or product may differ regarding some of the other characteristics that need to be considered while conducting a selection process. Each technology will be covered in depth in Section 6, but many of the general adhesive characteristics are listed below.

Moisture sensitivity: Some adhesives are sensitive to moisture and may need to be stored under special conditions or used within a certain time frame once removed from the protective packaging.

Temperature sensitivity: Particularly with 1C epoxies (heat curing technology), adhesives may need to be frozen to maintain performance and prevent curing. Other technologies may need to be refrigerated to extend shelf life and performance.

Temperature-sensitive viscosity: Many adhesives will become difficult to dispense at lower temperatures due to increased viscosity. Likewise at higher temperatures, the viscosity may decrease enough to cause issues with dispensing and bead placement.

Cure time: Cure time will be affected if the adhesive is a 1C or 2C product. As a general rule, 2C adhesives have shorter cure times than 1C adhesives (with exceptions).

One-component (1C): These adhesives usually do not require special dispensing equipment and are easy to use but generally have longer cure times. They will also usually have more specific storage requirements, as they are likely to be moisture cure or heat cure.

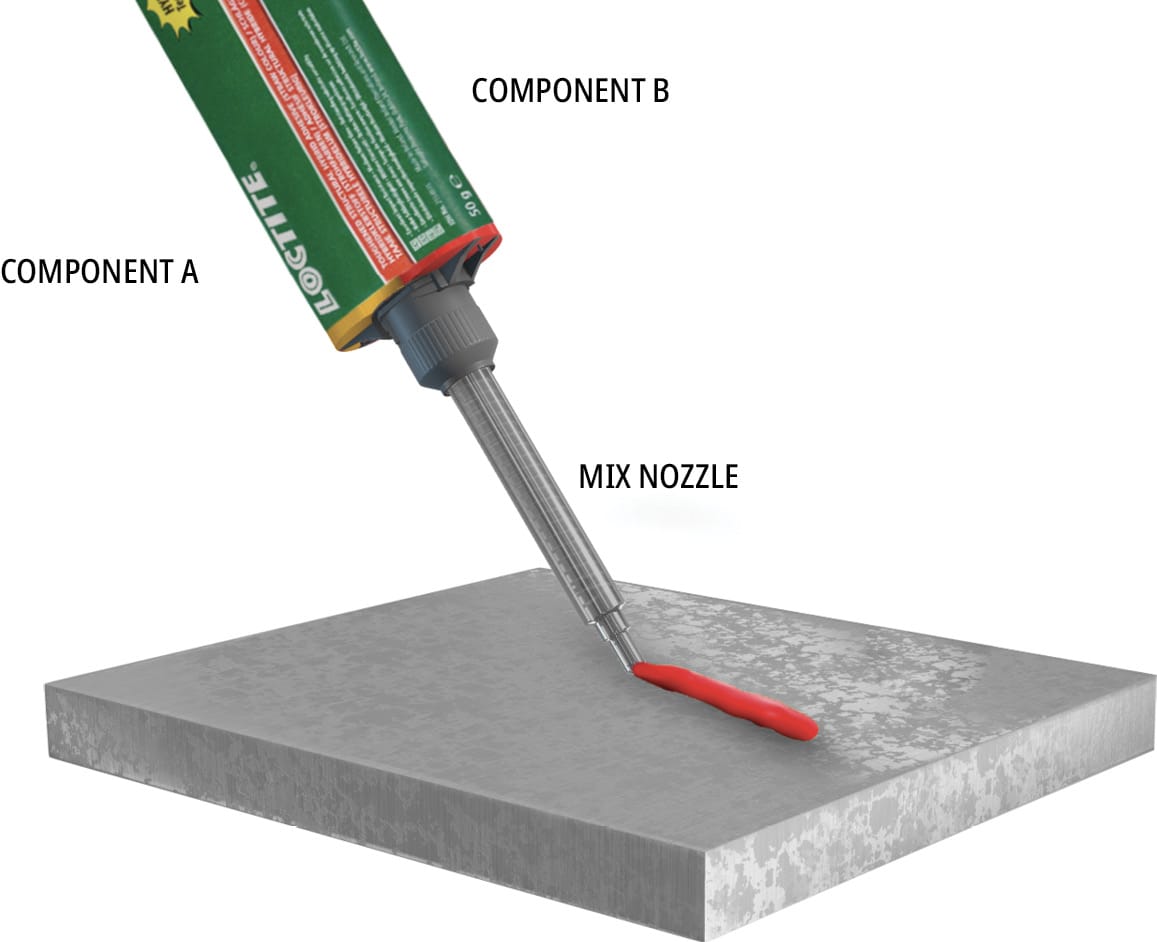

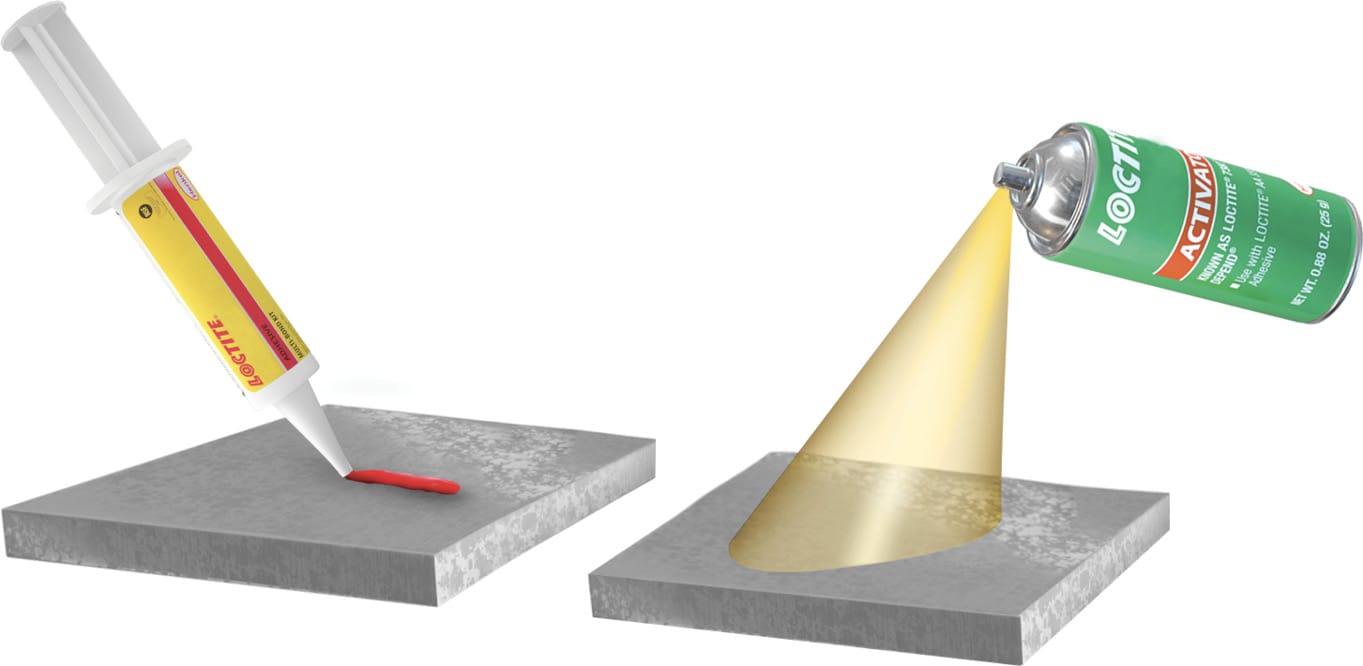

Two-component (2C): These adhesives contain separated components and, as a general rule, are more stable to varied environmental conditions. Curing will only begin when the two components are mixed together, which may be accomplished using a static mix nozzle or an activator.

Mixing ratio: With 2C adhesives, attention to the specific mix ratio is required to ensure desired cured adhesive performance and results. As a general rule, high-performance adhesives will come pre-metered in dual cartridges designed to dispense the correct ratio. With larger dispensing equipment designed to metre the adhesive at specific ratios, extra attention is required.

Pot life: For 2C adhesives, there is a finite application window called pot life (covered in detail in Section 2).

UV light sensitivity: Some adhesives will react with UV light by design. These adhesives must be stored and dispensed in ‘UV safe’ environments to prevent premature curing.

Consumables: For 2C adhesives, the use of static mix nozzles (covered in Section 6) and extra planning, however minimal, will be required to ensure consumables are on hand.

Each characteristic should be evaluated to determine if it will fit into a production plan or if certain aspects will preclude an adhesive from consideration due to process challenges relating to the specific technology characteristic.