4.3.2 Mechanical Cleaning

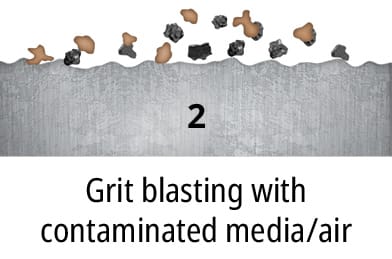

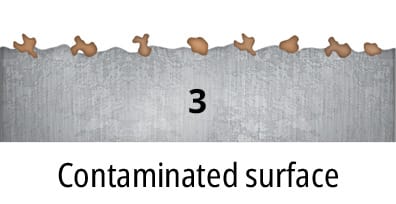

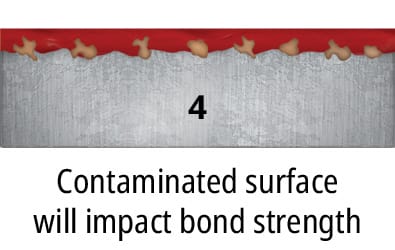

Mechanical cleaning methods are highly effective for surface preparation prior to bonding. They are also used to increase roughness and surface area for increased bond strength. Mechanical cleaning should be preceded and followed by solvent or aqueous cleaning to prevent oils and other contaminants from being driven deeper into the surface by abrasion and to clean up loose particles and lingering contaminants afterward.

There are many techniques for mechanical cleaning: by hand with sandpaper, steel wool or a wire rush or applied as a batch-cleaning with particle blasting methods.