2.2.5.1 Machining Accuracy

The machining accuracy of any component is affected by many elements, particularly two core factors:

1. Surface finish 2. Tolerance

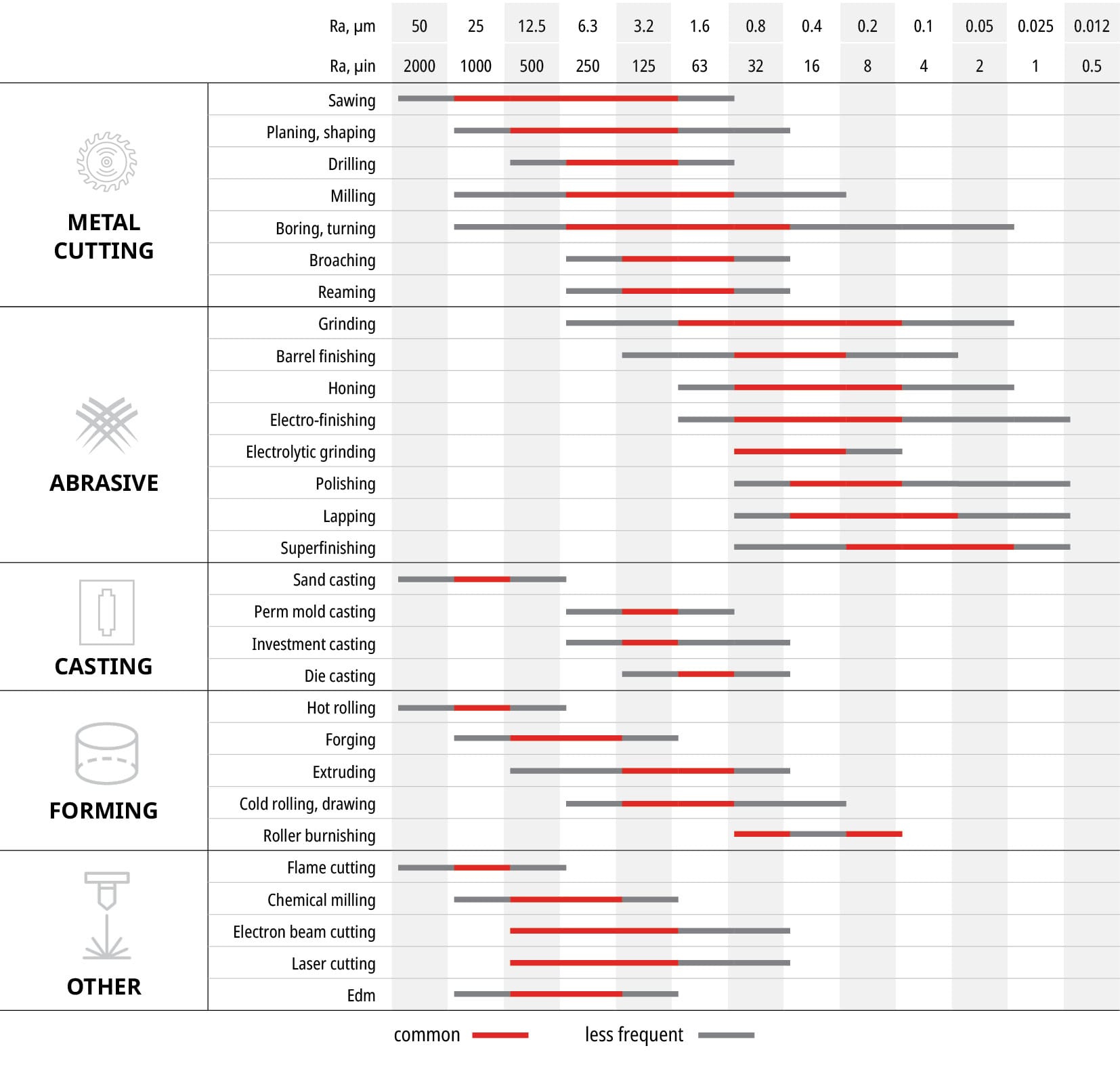

Grinding, honing, buffing, polishing, lapping and burnishing are common methods used to achieve the desired surface finish. Surface finish (Ra) is the average of the maximum (peaks) and minimum (valleys) values of the roughness profile (height) for the given material. A tighter or narrower range for these maximum and minimum values will result in a more refined surface finish and a smoother topology.

Changing the designated surface finish of a material from 3.2 µm to 0.8 µm (125 µin to 32 µin), for example, can significantly increase associated machining costs. The key reasons behind this increase are the manufacturing process changes and the number of machine passes required to achieve a finer surface finish, which increase the time spent producing a single component.

A designer may opt for an appropriate yet rough surface finish and high tolerance to realise the lowest machining costs. Other applications may allow for the combination of a rough or smooth surface finish with either tight or loose tolerances, depending on whether cost or performance is most critical. The surface finish and tolerances may affect the selection of an appropriate joining method. If the tolerances are tight, one can easily select a ‘Shrink Fit’ or ‘Bonded Press Fit’ to join a shaft and bearing assembly, for example.