5.2.1.4 Substrate Thermal Expansion and Contraction

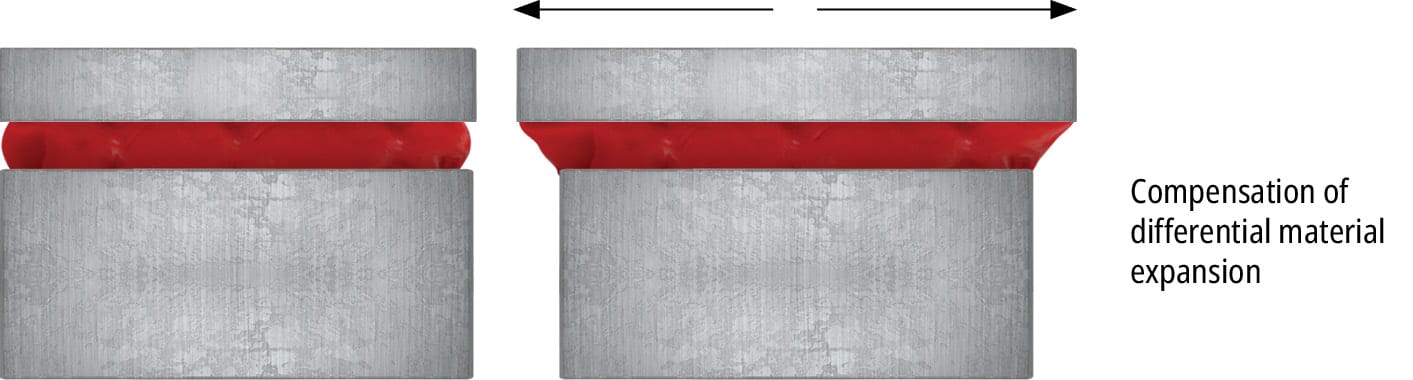

Substrates are also subject to microscopic movements during thermal expansion and contraction, which may cause adhesive bonds to fail if substrates and adhesives are incorrectly paired. One of the greatest advantages of adhesives is their ability to join dissimilar materials with ease. However, since all materials will expand or contract at different rates, an adhesive should be paired with the assembly that is able to expand and contract with the substrates (similar coefficient of thermal expansion) or is flexible enough to accommodate the differential expansion and contraction of the substrate.

For example, if we consider two one-metre beams, one made of steel and one made of aluminium, using principles and coefficients of linear thermal expansion, a temperature swing from 20°C (68°F) to 140°C (284°F) will cause the steel to expand 1.3 mm (0.05 in), while the aluminium would expand at a greater rate with a temperature of 2.8 mm (0.11 in) past the original one-metre length. Therefore, many adhesive properties have become relevant in creating a design that accounts for different rates of expansion. Assuming the direction of expansion is along the long axis, the adhesive must be able to withstand tensile load (see Section 4) as the forces applied are pushing/pulling the substrates relative to one another. If the adhesive is not sufficiently flexible or able to withstand the tensile load, the bond will fail.