2.2.1.2 Plastic

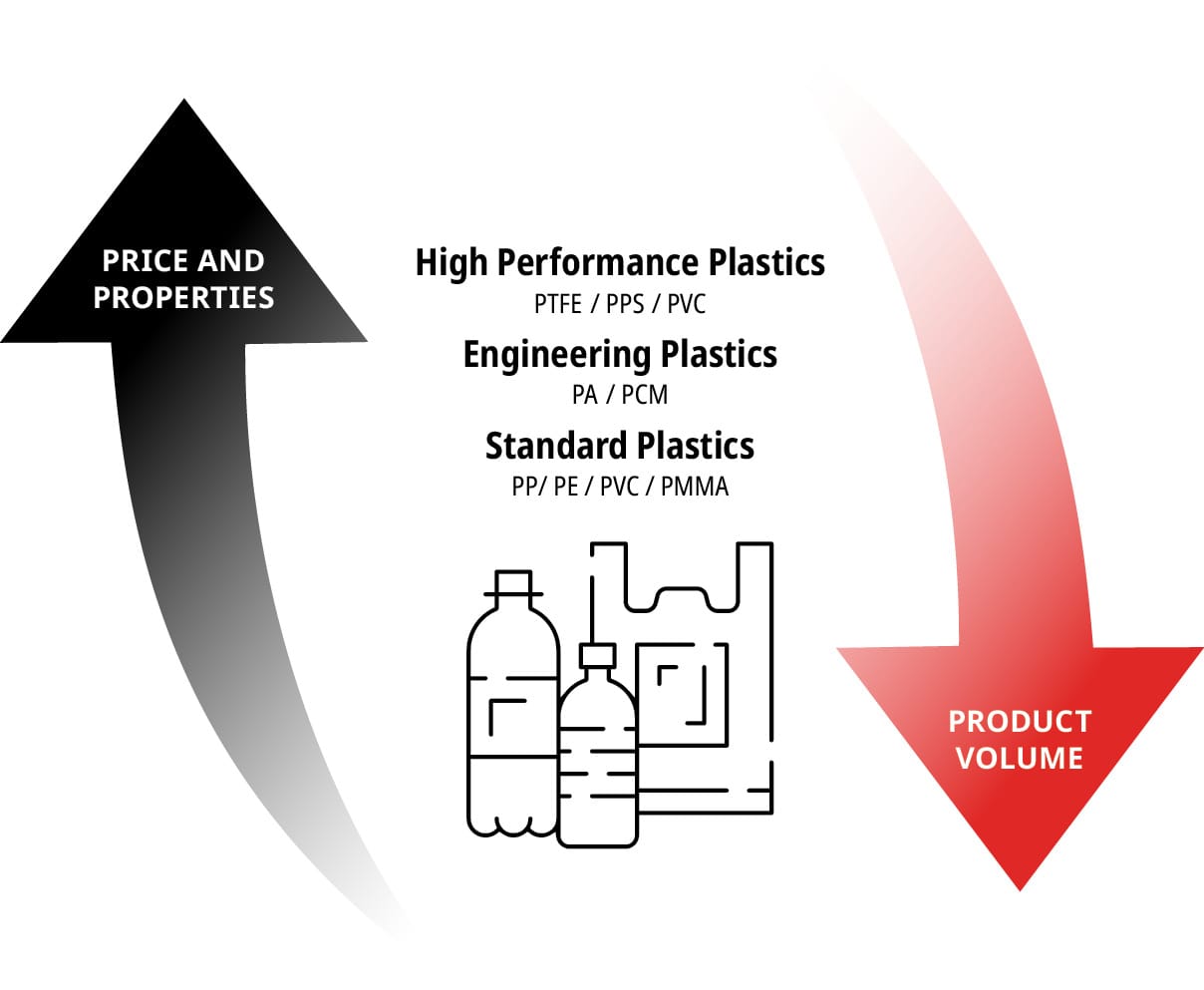

Plastics are becoming increasingly important in industry because of their versatile properties. A plastic (raw material, additives and production) is often selected as the most suitable material for the desired application due to its combination of machinability, hardness, elasticity, tensile and yield strength, temperature and heat resistance, environmental resistance and chemical resistance. An advantage of plastics over metals is their low weight, but they have limitations in mechanical and thermal stability by comparison; for example, very thin films of plastic can be difficult to bond. Figure 20 describes three main groups of plastics – standard plastics, engineering plastics and high-performance plastics – and their core representatives. For more detailed information regarding plastics, see the Loctite Design Guide for Bonding Plastics.

2.2.1.3 Rubber and Thermoplastic Elastomers

Figure 24 Different parts of rubber

Natural Rubber (NR) and thermoplastic elastomers are stable, resilient, easy to work with and highly durable materials. Elastomers are used where their characteristic properties are required, i.e. when rubber-elastic behaviour in the application temperature range is necessary. A distinction can be made between natural rubber (NR) and synthetic rubber, such as styrene-butadiene rubber (SBR), chloroprene rubber (CR), butyl rubber (IIR), ethylene propylene diene rubber (EPDM), butadiene-acrylonitrile rubber (NBR) and silicone rubber (Q). Even though synthetic rubbers have been further developed in recent years, the properties of NR remain unrivalled, especially in terms of permanent elasticity, cold elasticity and abrasion resistance.

According to DIN 7724 and ISO 472, further distinctions are made between elastomers and thermoplastic elastomers.

- Elastomers: rubber elasticity is present at temperatures below 20ºC (70ºF).

- Thermoplastic elastomer: rubber elasticity is present above 20ºC (70ºF) up to the decomposition temperature.

The following are typical properties of rubber and thermoplastic elastomers:

- They are elastic.

- They are not meltable.

- They do not have thermoplastic properties (thermoplastic elastomers are an exception to this).

- They are not soluble in solvents.

- They can swell when they come into contact with solvents.

For more detailed information regarding rubbers, see the Loctite Design Guide for Bonding Rubber and Thermoplastic Elastomers.