Section One Introduction to Joining

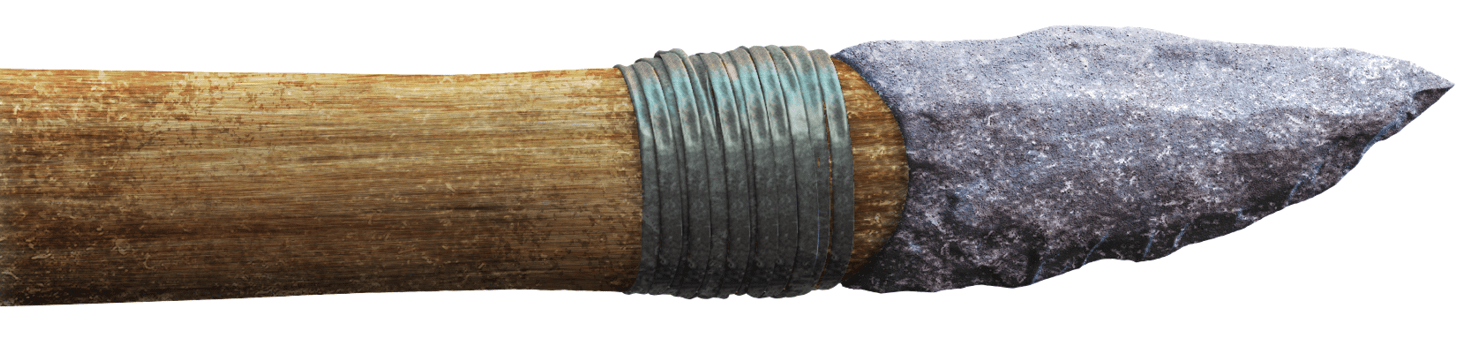

Humans have benefited from joining materials for thousands of years. The technological leaps made to create tools and structures gave early humans an important survival advantage by saving time and energy and increasing productivity and efficiency. From the earliest example of joining stone and organic materials, such as those illustrated in Figure 1, to today’s high-tech adhesives, humans have continually advanced the art and science of joining materials with a variety of techniques.

Archaeologists found the first evidence of adhesives in a 70,000-year-old burial site where broken pottery vessels had been repaired with sticky tree resins. Babylonians used a tar-like adhesive almost 6,000 years ago to glue ivory eyes into statues. Paintings and murals from around 1500 to 1000 B.C. depict the details of craftsmen gluing wood. Many cultures throughout the centuries employed glues made from animal hide, bones, milk, beeswax and grains in furniture, veneering and marquetry, and ship and weapon building. The treasures of the Egyptian pharaohs, including those discovered in the tomb of King Tutankhamen, were joined with animal-based adhesives.

By 1700, the use of glue was widespread, and technology saw rapid changes. The first commercial glue factory manufactured animal hide glue in Holland. Around 1750, the first glue patent was issued in Britain for fish glue. Patents quickly followed for adhesives using natural rubber (NR), animal bones, fish, starch and milk protein (casein).

The Industrial Revolution in the 18th to 19th centuries saw an explosion in technical breakthroughs in adhesive formulation. The first plastic polymer, cellulose nitrate, was synthesised from wood cellulose. Its first use was to replace ivory in the manufacture of billiard balls.

The plastic era dawned in 1910 with the introduction of Bakelite phenolic, a thermoset plastic. It was quickly followed by phenolic resin adhesives. The 1920s to 1940s were a time of rapid development of new synthetic plastics and rubbers, many of which played essential roles during World War II.

| 70,000 BC | 3000-4000 BC | 3400 BC | 3200-600 BC | 2000 BC | 400 BC | 1700 | 1770 | 1845 | 1881 | 1920s | 1934 | 1935 | 1950s | 1991 |

| First evidence of tree pitch used as an adhesive | Evidence of soldering and brazing | Egyptians invent nails (Bronze) | Evidence of the invention of rivets (Bronze) | Egyptians use liquid adhesives in wooden artifacts (animal glue) | Archimedes develops the ‘ screw principle’ | First commercial glue factory opens in Holland (animal glue) | Invention of a lathe capable of cutting threads on a fastener. ‘Invention‘ of the bolt | Pressure Sensitive Adhesive (Tape) invented | August De Meritens invents welding (Electical Arc) | Synthetic adhesives first commercial production | Epoxy adhesives patented in Germany | Howard Hughes invents the flush rivet | Polyurethane adhesives widely adopted | Friction stir welding invented and proven in the UK |

Today, adhesives made from animal by-products have been almost entirely supplanted by synthetic formulations. The development of adhesives alongside plastics and elastomers has enabled formulators to manipulate adhesive properties such as flexibility, toughness, curing or setting time, temperature and chemical resistance.

These new adhesives are so versatile and prevalent in our society that they are nearly invisible. If you are reading this on a screen or in a printed book, are sitting on furniture, in a car or on an aeroplane and are wearing shoes, jewellery or a smart watch, then you are surrounded by things held together, coated, protected or enhanced in some way by adhesives.

Today, adhesives hold our world together. The next section summarises some other common methods of joining materials.