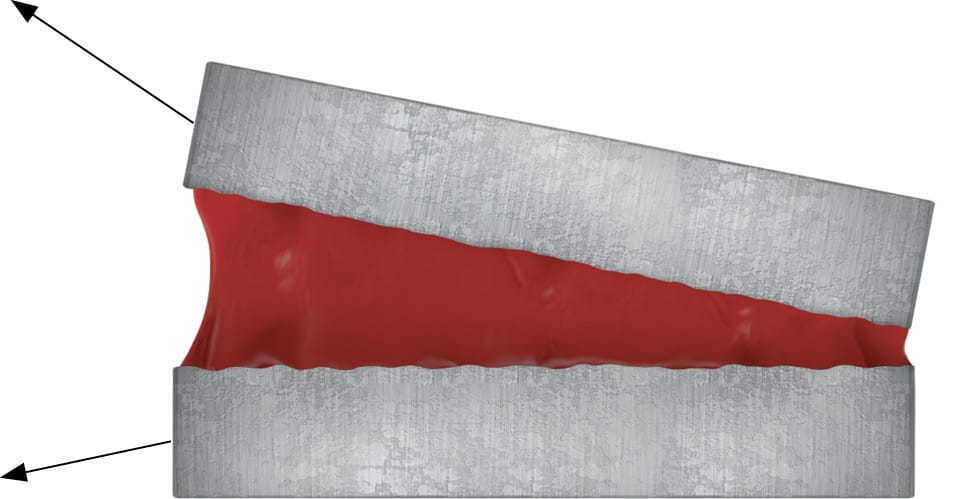

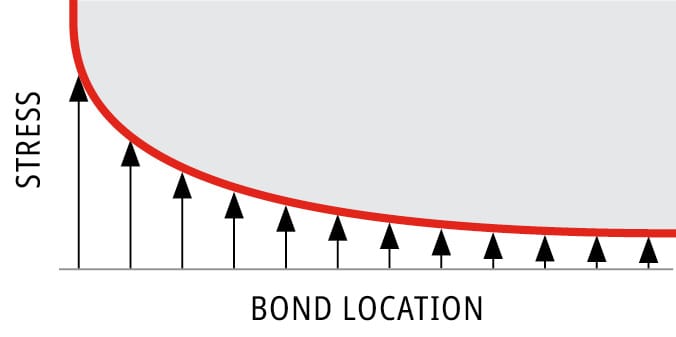

4.4.5 Cleavage Stress

Cleavage stress occurs when rigid substrates are opened at one end. Standardised tests to simulate cleavage stresses are done by gripping the ends and pulling apart or by driving a wedge between the substrates through the adhesive layer. This test is particularly important for measuring properties related to crack propagation in adhesives.

4.4.6 Impact Stress

Impact is dynamic stress at high speed. Impact stress may be applied as compression, tension, shear, cleavage, peel or any combination of these. The toughness of the substrate and the adhesive will be key in resisting impact stress. A strong material under static loading may fail under impact if it is brittle.

The impact resistance of a material or an assembly depends on its ability to move or deform to accommodate the impact internally. In a bonded assembly, the toughness of the substrate and adhesive and how the geometry distributes the impact throughout will determine the assembly’s toughness and resistance to impact.

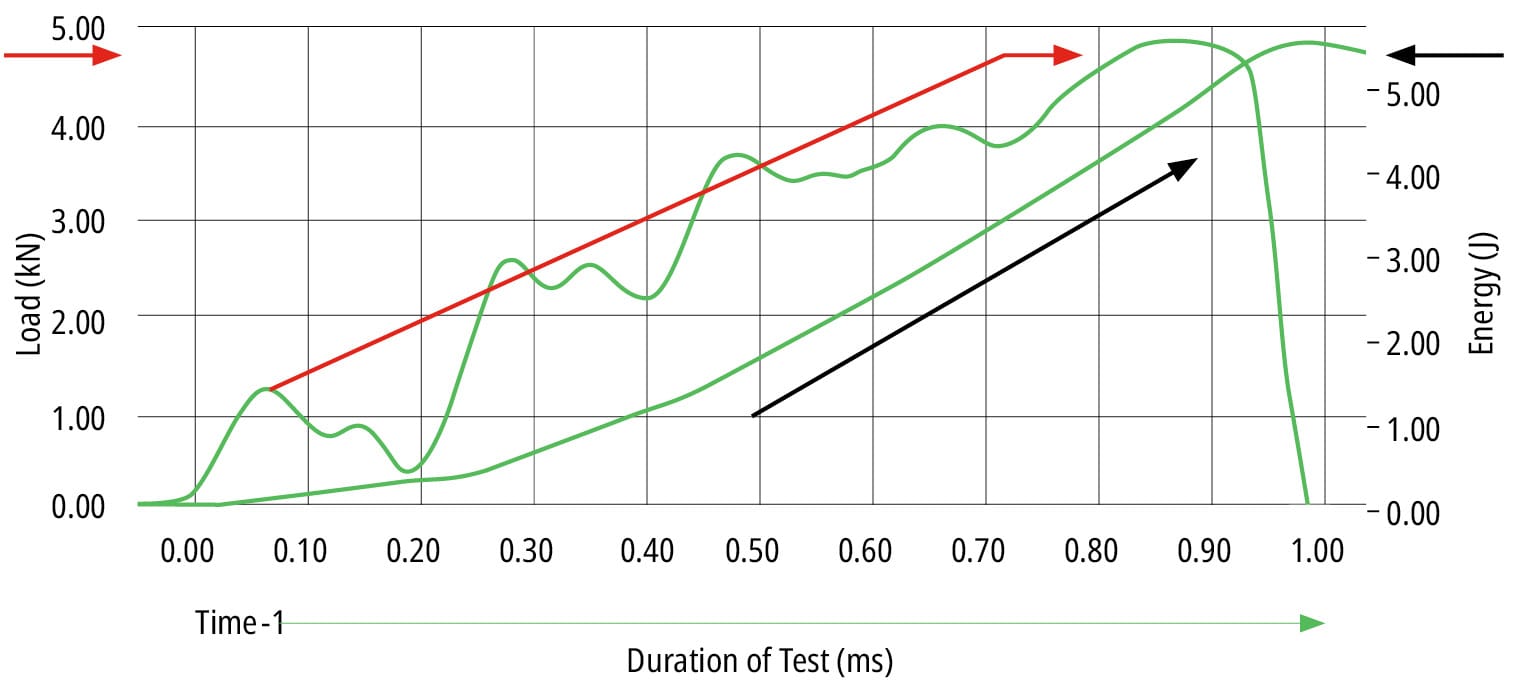

There are many tests for impact resistance, including drop tests (compression), side-impact (shear) and wedge impact (cleavage). Testing may be done on homogenous cured samples or assemblies, either standard test specimens or end-use assemblies. Results are typically reported in units of work (force x displacement), or joules, required to break the sample bond. The graph in Figure 100 illustrates other useful information such as joint behaviour and force to initiate failure.

Impact test software produces a dynamic load graph that starts when the sample is first impacted and records the loading of the sample until rupture. Whereas static testing may be measured in seconds or minutes, an impact test is measured in milliseconds.

The upper jagged green/red lines indicate the load applied to the sample over time. When the load drops below zero, the sample has broken.

The lower green line/blue lines follow the total absorbed energy over time and level off when the sample breaks, showing that energy is no longer being absorbed.