6.7.1 Polyolefin (PO) & Ethyl Vinyl Acetate Hotmelts

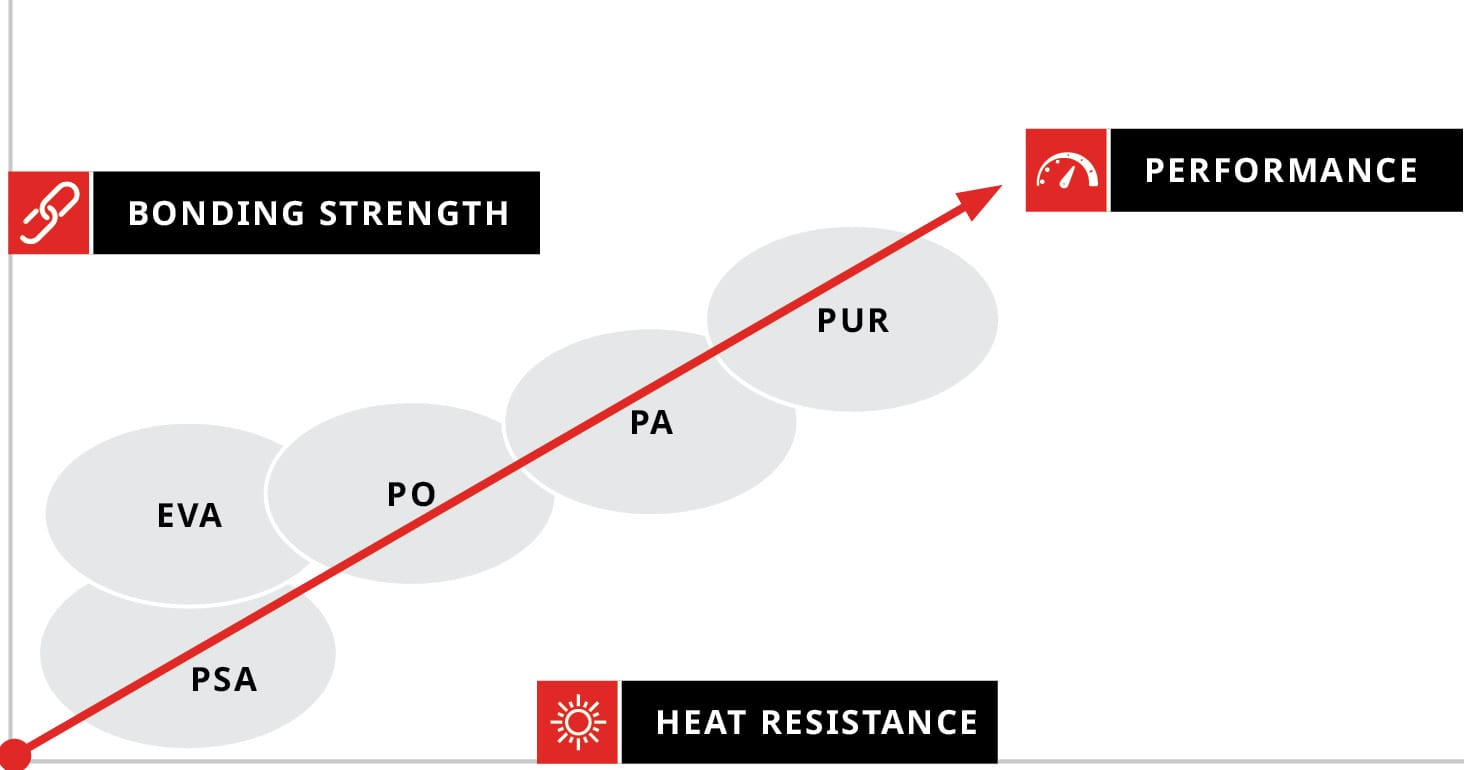

PO hotmelts are made from polyolefin copolymers. By tuning the crystallinity and molecular weight of polyolefins, products with different open times and bonding strengths can be developed. Ethylene vinyl acetate (EVA) is a class of crystalline polymers with a wide range of melting points. As the weight percentage of vinyl acetate increases, the material shifts from high crystallinity to high amorphous.

Both PO hotmelt and EVA hotmelts are widely used in paper, cardboard, wood and fabric bonding. Compounded versions can be used for non-load-bearing applications up to about 70°C (158°F). EVAs and PO hotmelts represent the highest volume of hot-melt adhesives used, primarily in packaging and wood assembly applications.31

6.7.2 polyamide (PA) Hotmelts

PA Hotmelts are made from the condensation of dimeric acids and diamines. They are supplied in pellet form and are solid at room temperature. They have high thermal stability, high melting points and good chemical resistance to many compounds, including many common solvents, plasticisers and oils. Compared to other hotmelts, such as EVA and PO, PA hotmelts offer higher creep resistance under load and better flame retardancy and heat stability. Many grades are thermally stable up to 160°C (320°F).31

30) Charles W. Paul, Adhesion Science and Engineering. Elsevier Science, Amsterdam, 2002.

31) Charles R. Frihart, ‘Specific adhesion model for bonding hot-melt polyamides to vinyl,‘ International Journal of Adhesion and Adhesive (2004), Vol 24. 415-422.